Advanced Carbon Fiber Solutions for Modern Industries #

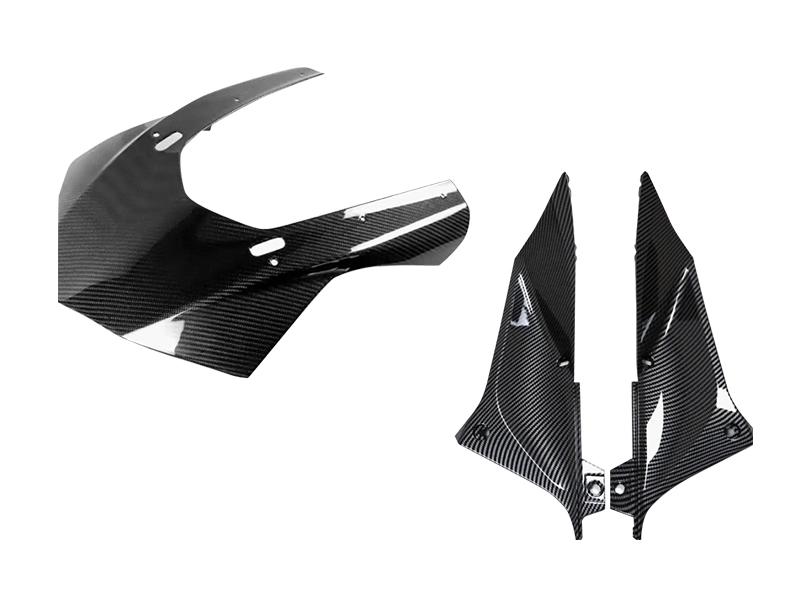

Carbon fiber composites have become a cornerstone in high-performance engineering, offering a unique combination of strength, durability, and lightweight characteristics. From precision RC components to advanced automotive and marine parts, carbon fiber is reshaping product development across a wide spectrum of industries.

The Value of Carbon Fiber Composites #

- Exceptional Strength & Durability: Carbon fiber materials, including sheets and reinforced polymers, are engineered for demanding applications where performance is critical.

- Lightweight Performance: With a density of approximately 1.6 g/cm³, carbon fiber delivers significant weight savings without compromising structural integrity.

- Versatile Applications: Industries such as RC, automotive, drone technology, sports equipment, and electronics benefit from carbon fiber’s unmatched stiffness, heat resistance, and design flexibility.

Industry Focus #

- 50% Sports and RC

- 30% Marine and Boat

- 20% Other sectors

Our Commitment to Your Business #

- Maximum Value: We ensure you receive the best return on your investment.

- Competitive Pricing: Our rates are both reasonable and market-driven.

- Customization: Solutions tailored to your specific requirements.

- Quality Assurance: We never compromise on quality standards.

- Timely Delivery: Reliable and punctual order fulfillment.

Fast Turnaround #

- 24 hours: Quotation

- 35 days: Standard production

- 72 hours: Express service

- 25 days: Rush order delivery

Technical Data: Carbon Fiber at a Glance #

- Density: ~1.6 g/cm³

- Tensile Strength: Standard modulus around 300 ksi (varies by grade)

- Modulus of Elasticity: 15-50 Msi

- Thermal Conductivity: 1-10 W/m·K (low)

- Electrical Conductivity: Conductive due to graphite structure

- Fatigue Resistance: Generally good, depending on application

- Corrosion Resistance: Inherently resistant

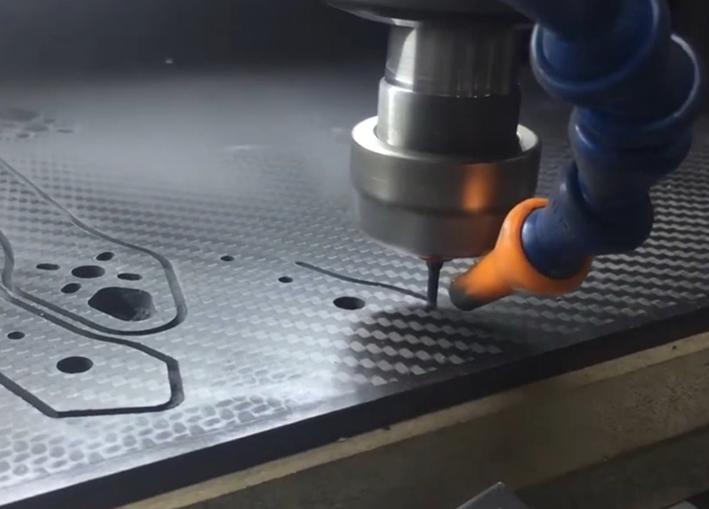

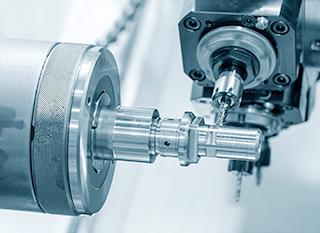

CNC Milling of Carbon Fiber Components #

CNC milling enables the precise shaping of carbon fiber materials. The process involves:

- Design and material selection

- Machine and tool setup

- Tool path generation

- Milling and cooling

- Finishing and inspection

Skilled operators leverage carbon fiber’s unique properties to deliver accurate, high-quality results.

Vacuum Infusion: Forming Carbon Fiber Components #

Vacuum infusion is a preferred method for producing strong, lightweight carbon fiber parts:

- Dry carbon fiber fabric is placed in a mold

- A vacuum bag is sealed over the assembly

- Resin is introduced under vacuum, saturating the fabric

- After curing, a uniform, lightweight composite part is produced

This technique is widely used in aerospace and automotive industries for its consistency and ability to create complex shapes.

Material Options for Carbon Fiber Fabrication #

- Standard Modulus (SM or T300): Balanced strength and stiffness

- Intermediate Modulus (IM or T700): Higher strength and stiffness, suitable for aerospace

- High Modulus (HM or T800): Exceptional stiffness, ideal for sports equipment

- Ultra High Modulus (UHM or T1000): Extreme stiffness for specialized uses

- Pitch-Based: Enhanced heat resistance for industrial applications

- Pan-Based: Common, cost-effective, and balanced performance

- Spread Tow: Superior mechanical properties for high-performance needs

- Unidirectional: Maximum strength along a single axis

- Woven Fabric: Various weaves and strength levels

- Hybrid: Blended with Kevlar or fiberglass for tailored properties

Process Overview: Vacuum Forming & CNC Milling #

Vacuum Forming:

- Carbon fiber fabric is laid on a mold

- Heat activates the resin

- Vacuum removes air, forming the material to the mold

- Curing solidifies the final shape

CNC Milling:

- Digital model is created

- Carbon fiber sheet is secured

- CNC machine follows programmed paths

- Specialized tools manage the abrasive nature of carbon fiber

- Finishing ensures the desired surface quality

Both methods enable the production of precise, high-performance carbon fiber components for a variety of applications.

Surface Treatment: Enhancing Carbon Fiber Components #

Wax treatment is a common surface enhancement for carbon fiber, offering:

- Protection: Shields against moisture, UV rays, and environmental factors

- Enhanced Appearance: Provides a glossy, attractive finish

- Smooth Surface: Reduces drag and improves aerodynamics

- Water Repellency: Creates hydrophobic surfaces for water resistance

- Easy Cleaning: Minimizes dirt and debris adhesion

- UV Resistance: Some waxes include UV inhibitors to prevent fading

Selecting the right wax and application method is essential for maximizing the benefits based on the intended use of the component.

Streamlined Manufacturing in Three Steps #

- Get a Quote: Submit your manufacturing drawing and order details. Receive a quote within 48 hours.

- Quality Control: We select the right manufacturer, oversee production, and ensure quality standards are met.

- Receive Components: Your components are delivered, quality-tested, and accompanied by a detailed test certificate.

Customer Experiences #

What Our Clients Say #

- “Exceptional service and high-quality CNC parts have accelerated our research projects.”

- “Outstanding service and craftsmanship added value to our espresso coffee grinder.”

- “Fast delivery and excellent quality exceeded our expectations.”

- “Moving production to DMS was the right decision—quality speaks for itself.”

Bringing Your Ideas to Life #

We are more than a supplier; we are a partner in your success, transforming your concepts into reality with advanced carbon fiber solutions.