Advanced CNC Milling Capabilities for Demanding Applications #

Direct Manufacture Supplier International Inc. (DMS) delivers high-precision CNC milling services, leveraging advanced 3-, 4-, and 5-axis machining centers. Our expertise enables us to produce complex geometries with tight tolerances, supporting industries such as aerospace, medical devices, automation, and consumer electronics.

Comprehensive CNC Milling Services #

- High-Precision Machining: Utilizing state-of-the-art 3-, 4-, and 5-axis CNC machines, we manufacture components with exceptional accuracy and repeatability.

- Versatile Production: From prototypes and small batches to full-scale production runs, our skilled team ensures consistent quality at every stage.

- Material Flexibility: We machine a broad spectrum of materials, including aluminum, stainless steel, titanium, copper, and engineering plastics.

Streamlined Production Processes #

Rapid Prototyping #

Transform your CAD designs into functional CNC-milled prototypes quickly. Our rapid prototyping process allows for efficient testing and refinement, reducing costly errors and accelerating your product’s time-to-market.

Bridge Production #

Seamlessly transition from prototype to production with our bridge manufacturing solutions. We help mitigate scaling risks and maintain consistent quality throughout the transition phases.

Demand Production #

Respond to market needs with on-demand CNC milling. Our flexible production model ensures you meet deadlines, manage inventory efficiently, and receive high-quality components exactly when needed.

Materials and Capabilities #

We offer CNC milling for a wide range of materials, including:

- Aluminum: 7075, 6061-T6, A2024, A5052, A6063, A6463, A6082

- Stainless Steel: 304, 304L, 316, 420J2, 430, 434, 442

- Steel: 12L14, 12L15, 1018, S1020, 1040, 1045, SCM430, SCM415, SCM435, SCM440, SNCM415, 4140, 4130, 4340

- Brass: C36000, CDA3600, CCDA3604

- Plastics: EPDM, Delrin, Lexan, Nylon 66, Nylon 6, POM, Peak, PP, PE, Acetal

- Titanium: Grade 1 to Grade 28

- Magnesium: AMS 4375 - AZ31B-O Sheet/Plate, AMS 4376 - AZ31B-H26 Plate

Technical Data #

- Traverse Paths:

- X-axis: up to 10,000 mm

- Y-axis: up to 4,300 mm

- Z-axis: up to 1,250 mm

- Tolerances: from +/- 0.005 mm

- Batch Sizes: from 1 piece

For more information on material properties, refer to the steel material guide and aluminum material catalogue.

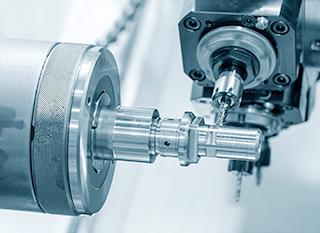

CNC Milling Process Overview #

CNC milling is a subtractive manufacturing process that removes material from solid blocks using rotating cutting tools. Unlike traditional methods, CNC machines follow precise, pre-programmed toolpaths to create complex shapes with tight tolerances—ideal for manufacturing CNC billet parts.

The Milling Process #

Using custom NC code, tools move at high speed into a clamped workpiece, ensuring repeatability and precision. At DMS, we utilize Haas 3-axis and 5-axis milling machines to handle everything from simple shapes to complex multi-surface parts.

Why Choose DMS CNC Milling? #

- Minimizing machining and setup time

- Maximizing dimensional accuracy

- Increasing production efficiency for high-volume orders

Our approach ensures faster turnaround, better part quality, and lower production costs, whether for prototyping or full-scale production.

5-Axis CNC Machining: Flexibility and Precision #

Our DMG MORI 5-axis CNC machines combine 3 linear axes (X, Y, Z) with 2 rotary axes, offering unmatched flexibility and precision. This configuration allows for machining of complex, intricate parts with greater accuracy in a single setup, reducing repositioning time and improving part quality.

How 5-Axis CNC Machines Work #

By utilizing rotary axes in conjunction with linear axes, 5-axis machines access every surface of the workpiece for efficient, precise machining. This eliminates the need for multiple setups, increasing throughput and reducing errors.

Types of 5-Axis Machining #

- Continuous 5-Axis: Simultaneous movement of all axes, ideal for complex geometries with tight tolerances.

- Indexed 5-Axis: Rotary axes are used step-by-step for simpler shapes, reducing complexity.

Key Advantages #

- Reduced setup time: Machine multiple sides in one go

- Improved accuracy: Fewer handling errors and better tool access

- Higher efficiency: Faster cycle times for high-precision parts

5-axis technology is widely used in industries like aerospace, medical devices, and automotive for its precision, reliability, and efficiency in producing high-quality, repeatable parts.

Learn more about 5-axis machining fundamentals

Surface Treatment Solutions #

At DMS, we recognize the importance of refinement, appearance, and protection against wear and corrosion. Our surface treatment options enhance the aesthetics, durability, and functionality of the components we manufacture. Available treatments include:

- Sandblasting

- Paint

- Anodizing

- Powder coating

- Electroless nickel

- Galvanizing

- Passivation

- Chromate

Frequently Asked Questions #

What makes DMS different from other CNC suppliers?

DMS combines engineering expertise, global supply reach, and strict quality control. With over 500+ audited suppliers, advanced 3- to 5-axis CNC capabilities, and a proven track record in precision and reliability, we deliver high-quality parts on time, every time.

Can DMS support just-in-time (JIT) or scheduled delivery orders?

Yes. We offer flexible logistics solutions, including JIT and scheduled deliveries, aligning production and shipping timelines to reduce inventory costs and improve workflow efficiency.

What industries does DMS serve?

We serve a wide range of industries, including:

- Aerospace & Defense

- Medical & Dental Devices

- Automotive & E-Mobility

- Industrial Equipment

- Semiconductors & Electronics

- Robotics & Automation

- Energy & Green Tech

Our engineering team understands the specific standards and certifications required in each sector, ensuring reliable, high-performance components.

Can DMS support re-orders or repeat jobs with updated specs?

Yes. We securely store job history, drawings, and inspection data, allowing fast turnaround on repeat orders. If specifications change, our team reviews updates to ensure smooth, accurate production.

Do you accept blanket orders or long-term contracts?

Yes. We support blanket orders and long-term supply agreements to help clients secure pricing, reduce lead times, and manage inventory efficiently.

How do you ensure part confidentiality and IP protection?

Protecting your intellectual property is a top priority. We enforce strict confidentiality agreements with all employees, suppliers, and partners. All designs and data are stored securely with encrypted systems and access control measures. NDAs are available upon request.

Component Types and Applications #

Our CNC milling capabilities cover a broad spectrum of components, including adaptors, caps, hubs, flanges, rollers, connectors, knobs, plungers, seals, bodies, mounts, guides, supports, bushings, dowels, blocks, couplings, nozzles, and plates.

Additional Manufacturing Services #

DMS also offers:

- CNC Turning

- Aluminum Extrusion

- Metal Pipe & Sheet Metal Bending

- Metal Welding

- Metal Forging

- Aluminum Die Casting

- Plastic Injection Molding

- OEM Manufacturing Service

CNC turning

CNC turning

CNC Milling

CNC Milling

DMS Aluminum Extrusion Service

DMS Aluminum Extrusion Service

DMS Metal Pipe & Sheet Metal Bending Service

DMS Metal Pipe & Sheet Metal Bending Service

DMS Metal welding service

DMS Metal welding service

DMS Metal forging service

DMS Metal forging service

DMS Aluminum Die Casting Service

DMS Aluminum Die Casting Service

DMS Plastic Injection Molding Service

DMS Plastic Injection Molding Service

DMS OEM Manufacturing Service

DMS OEM Manufacturing Service

Customer Feedback #

What Our Clients Say #

- “We greatly appreciate the exceptional service provided by you, great good looking CNC parts, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.” — Tony Fred, Senior Buyer

- “Your outstanding service is super impressive. Your great job on our stainless steel bending case makes our espresso coffee grinder added value. It really makes it look nice, super well done.” — Mich Stark, R & D Engineer

- “DMS delivered our parts very fast with excellent quality that is what we are expecting, hopefully you will see our next order very soon.” — Aline Turner, SR procurement

- “Now I can say it is a right decision to move our production from China to your company, you guys are awesome, all the marine pads looks shiny no scratch founded, it is 8% more expensive compare to China but quality talks, we will keep buying more items from you for sure.” — Iris Joe, Engineering Designer

Our Commitment #

- Maximum Value: Guaranteeing the best value for your investment

- Competitive Pricing: Reasonable and transparent pricing

- Customization: Tailored solutions based on customer preferences

- Quality Assurance: No compromise on quality

- On-Time Delivery: Reliable and punctual delivery for every order