Precision and Versatility in Custom Aluminum Extrusion #

At DMS, we bring deep expertise in both aluminum and plastic extrusion, delivering custom extruded products that align with your unique design and industry requirements. Our advanced extrusion technology supports everything from intricate profiles to large-scale production, ensuring precision, consistency, and high-quality results at every stage.

Why Choose DMS for Extrusion? #

- Maximum Value: We guarantee optimal value for your investment, focusing on efficiency and quality.

- Competitive Pricing: Our pricing structure is both competitive and reasonable, making high-quality extrusion accessible.

- Customization: Every project is tailored to customer preferences, ensuring your specifications are met.

- Uncompromising Quality: We maintain strict quality standards throughout the production process.

- Reliable Delivery: Timely delivery is a core commitment, with express and standard options available.

Fast Turnaround:

- Quotation within 24 hours

- Standard production in 35 days

- Express service available within 72 hours

Materials and Capabilities #

Our extrusion services are supported by a broad selection of materials and technical capabilities:

- Material Thickness: 0.3 mm – 25 mm

- Dimensions: Minimum 3 x 1 x 0.8 mm

- Component Weight: Up to 18 kg

- Tolerances: Up to 0.1 mm

- Closing Force: Up to 400 kg

- Heat Treatment: HRC, HRB (T4, T5, T6)

Available Materials #

- Aluminum Series: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

- Magnesium Series: AMS 4375 - AZ31B-O Sheet/Plate, AMS 4376 - AZ31B-H26 Plate

The Extrusion Process Explained #

Extrusion involves heating raw alloy material and injecting it at high pressure into a mold cavity. Once cooled and solidified, the part is extracted and can undergo further refinements such as T5 or T6 heat treatment. The process allows for the creation of continuous profiles, which are then cut or further processed as needed.

Surface Treatment Options #

To enhance the performance and appearance of your components, we offer a comprehensive range of surface treatments:

- Burnishing

- Anodizing

- Chromate

- Hard anodizing

- Oxidizing

- Liquid coating

- Powder coating

- Electroless nickel

These treatments provide protection against wear and corrosion, as well as improved aesthetics.

Integrated Manufacturing Solutions #

Our capabilities extend beyond extrusion, offering a full suite of manufacturing services:

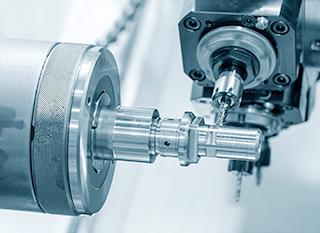

- CNC Turning

- CNC Milling

- Metal Pipe & Sheet Metal Bending

- Metal Welding

- Metal Forging

- Aluminum Die Casting

- Plastic Injection Molding

- OEM Manufacturer Service

Streamlined Sourcing in Three Steps #

- Get a Quote: Send your manufacturing drawing and order details. Receive a quote within 48 hours.

- Quality Control: We select the right manufacturer, oversee production, and ensure quality control.

- Receive Components: Your quality-tested components are delivered with a detailed test certificate.

Customer Experiences #

Our clients consistently highlight our commitment to quality, speed, and service:

- “Exceptional service contributed to the success of our research projects and enabled breakthroughs in record time.” — Tony Fred, Senior Buyer

- “Outstanding service and excellent work on our stainless steel bending case added significant value to our espresso coffee grinder.” — Mich Stark, R & D Engineer

- “Parts delivered quickly and with excellent quality, exactly as expected.” — Aline Turner, SR Procurement

- “Moving production from China to DMS was the right decision. Quality speaks for itself.” — Iris Joe, Engineering Designer

Image Gallery #

Direct Manufacturer Supplier International Inc.

No. 75-1, Ln. 217, Dazhou Rd., Dashe Vil., Shengang Dist., Taichung City 42941, Taiwan (R.O.C.)

Tel: +886-4-25293061

Email: info@dmsgroup-tw.com / sales@turningparts.com.tw