Unlocking the Potential of Metal Forging for Your Projects #

Metal forging stands as a cornerstone in the manufacturing of durable, high-performance components. At DMS, we specialize in both open-die and closed-die forging, utilizing hot and cold processes to deliver precision-forged parts in steel, aluminum, and more. Our capabilities support a broad spectrum of industries, from industrial machinery to custom dirt bike components, ensuring each project benefits from our commitment to quality and innovation.

Why Choose Our Forging Services? #

- Maximum Value: We focus on delivering the best possible value for every project.

- Competitive Pricing: Our rates are both reasonable and market-competitive.

- Customization: Solutions are tailored to your specific requirements.

- Uncompromising Quality: We adhere to strict quality standards at every stage.

- Reliable Delivery: Timely completion and shipment are always a priority.

Fast Turnaround #

- Quotation: Within 24 hours

- Production: As fast as 35 days

- Express Service: 72-hour turnaround available

- Rush Orders: Delivery in as little as 25 days

Our Forging Process: From Concept to Completion #

- Select the appropriate metal for forging.

- Heat the metal (for hot forging) or work it at room temperature (for cold forging).

- Shape the metal using precision dies.

- Apply high force to deform and form the metal.

- Achieve the desired geometry through compression, stretching, or bending.

- Enhance strength via grain alignment.

- Trim and finish the forged part.

- Conduct thorough inspection for quality and specifications.

Forging is renowned for producing robust components with superior mechanical properties, making it ideal for demanding applications.

Technical Data at a Glance #

- Material Thickness: 0.5 mm – 30 mm

- Maximum Forging Size: 100 x 100 x 100 mm up to 1,500 x 1,500 x 6 mm

- Weight Range: 35 g to 22 kg

- Tolerances: Up to 0.1 mm

- Closing Force: 80 – 2,000 T

- Batch Sizes: 10 to 1,000 pieces

- Heat Treatment: HRC, HRB, T4, T5, T6

Materials We Work With #

- Stainless Steel:

- 300 Series: SUS303, SUS304, SUS304L, SUS316, SUS316L

- 400 Series: SUS420J2, SUS430, SUS434, SUS442

- Steel:

- Carbon Steel: 12L14, 12L15, 1018, S1020, 1030, 1040, 1045

- Cr-Mo: SCM430, SCM415, SCM435, SCM440

- Ni-Cr-Mo: SNCM415, 4140, 4130, 4340

- Aluminum: A2024, A5052, A6061, A6063, A6463, A6082, A7075

- Brass: CDA3600, CCDA3604

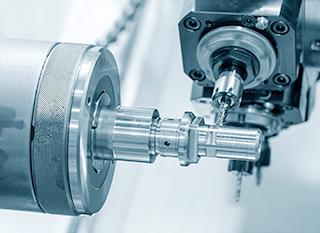

The Forging Manufacturing Process Explained #

Forging involves heating metal and applying compressive forces with dies to shape it. This process aligns the grain structure, resulting in parts with exceptional strength and durability. Forging is widely used across industries for its structural integrity and reliability.

Hot Forging #

Hot forging shapes metal at elevated temperatures, allowing for the creation of complex and large parts with enhanced mechanical properties.

Cold Forging #

Cold forging is performed at or near room temperature, producing precise and complex parts without the need for heating. This method offers improved dimensional accuracy and material efficiency.

Surface Treatment for Enhanced Performance #

We recognize the importance of refinement, appearance, and protection against wear and corrosion. Our surface treatment options include:

- Sandblasting

- Paint

- Anodizing

- Powder Coating

- Electroless Nickel

- Galvanizing

- Passivation

- Chromate

These treatments not only improve aesthetics but also extend the lifespan and functionality of your components.

Additional Manufacturing Capabilities #

Our expertise extends beyond forging to include:

CNC Turning

CNC Turning

CNC Milling

CNC Milling

Aluminum Extrusion

Aluminum Extrusion

Metal Pipe & Sheet Metal Bending

Metal Pipe & Sheet Metal Bending

Metal Welding Service

Metal Welding Service

Metal Forging

Metal Forging

Aluminum Die Casting

Aluminum Die Casting

Plastic Injection Molding

Plastic Injection Molding

OEM Manufacturer Service

OEM Manufacturer Service

Streamlined Sourcing in Three Steps #

- Get a Quote: Submit your manufacturing drawing and order details. Receive a quote within 48 hours.

- Quality Control: We select the right manufacturer, oversee production, and ensure rigorous quality checks.

- Receive Components: Your components arrive quality-tested, complete with a detailed test certificate.

We are your trusted partner for custom metal parts fabrication.

What Our Clients Say #

Tony Fred, Senior Buyer “We greatly appreciate the exceptional service provided, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.”

Mich Stark, R & D Engineer “Your outstanding service is super impressive. The work on our stainless steel bending case added value to our espresso coffee grinder. It looks great and is very well done.”

Aline Turner, SR Procurement “Thank you, DMS delivered our parts very fast with excellent quality. That is exactly what we expect. Looking forward to our next order.”

Iris Joe, Engineering Designer “Moving our production from China to DMS was the right decision. The marine pads look shiny with no scratches. Quality speaks for itself, and we will continue to order more.”