Advanced Approaches to Sheet Metal Cutting and Forming #

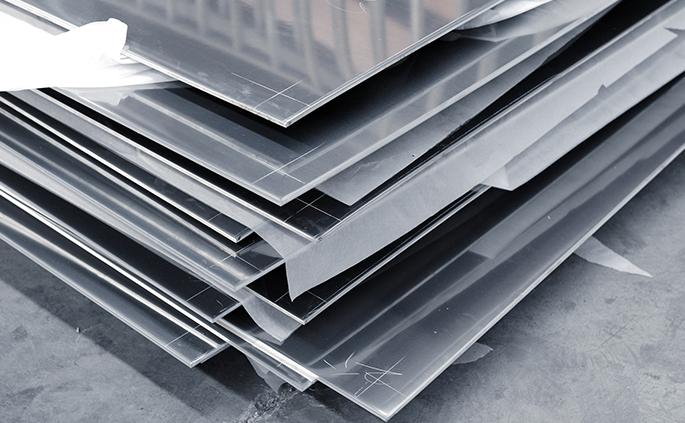

Whether you are a DIY enthusiast or an industrial manufacturer, our sheet metal cutting services are designed to deliver high-precision results tailored to your specific requirements. Utilizing state-of-the-art technologies such as laser cutting, CNC sheet metal cutting, water jet cutting, and plasma cutting, we ensure clean, accurate cuts for projects of any scale—from prototypes to full production runs.

Our commitment to efficiency, precision, and reliability is reflected in every step of our process, providing customized solutions that adapt to your needs.

Key Service Highlights #

- Maximum Value: We focus on delivering the best value for your investment.

- Competitive Pricing: Our pricing structure is both competitive and reasonable.

- Customization: Solutions are tailored to customer preferences and project specifications.

- Quality Assurance: We never compromise on quality.

- On-Time Delivery: Timely delivery is a core part of our service promise.

Fast Turnaround #

- Quotation: Within 24 hours

- Production: As fast as 35 days

- Express Service: Available in 72 hours

- Rush Order Delivery: As fast as 25 days

How Laser Cutting Works #

Laser cutting employs a focused laser beam to melt, burn, or vaporize materials along a computer-guided path. The intense heat allows for precise cuts with minimal heat-affected zones, making this technology versatile and widely used across industries for its accuracy and ability to process various materials.

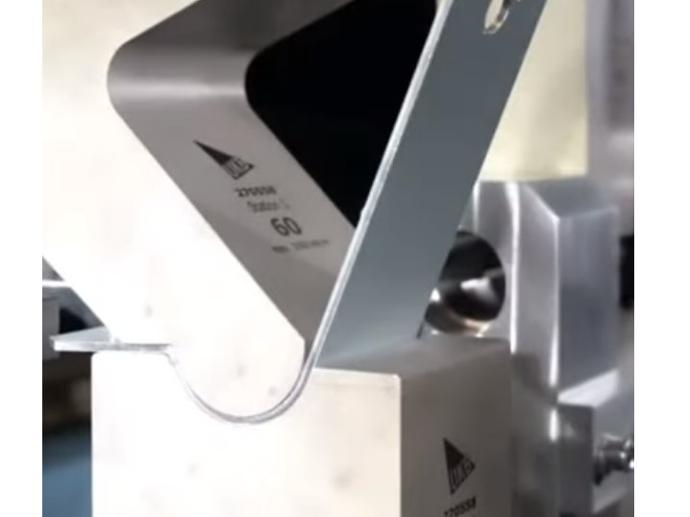

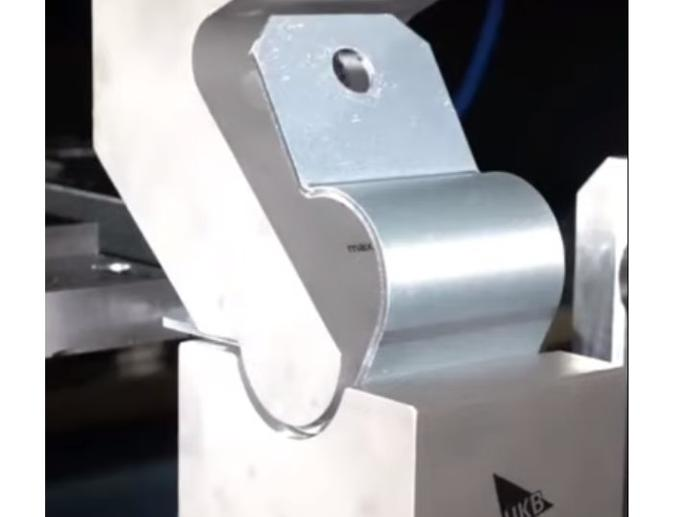

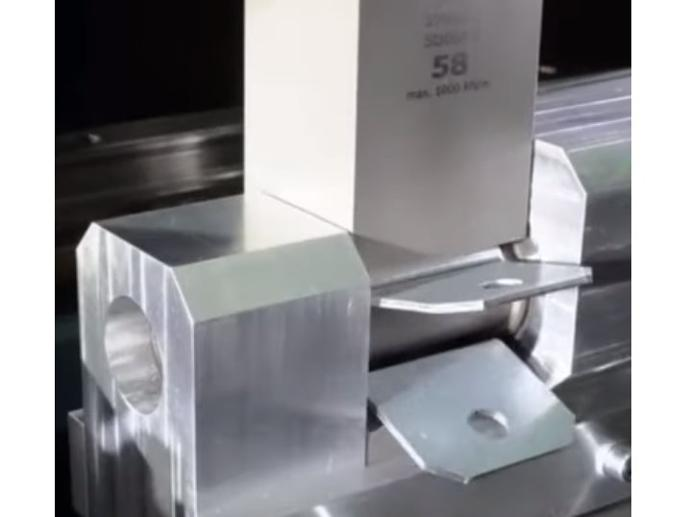

Integrated Bending and Forming Services #

Our capabilities extend beyond cutting to include metal sheet bending, cutting, and punching. This integrated approach ensures the prompt production of accurate components, whether working with metals or plastics. Our advanced processes are designed to meet diverse manufacturing needs with precision and speed.

Technical Data #

- Maximum Wall Thickness: 25 mm

- Minimum Wall Thickness: 0.2 mm

- Batch Sizes: From 1 piece

Materials Supported #

- Stainless Steel Series:

- 300 Series: SUS303, SUS304, SUS304L, SUS316, SUS316L, SUS317, SUS317L

- 400 Series: SUS420J2, SUS430, SUS434, SUS442

- Steel Series:

- Carbon Steel: 12L14, 12L15, 1018, 1117, 1141, S1020, 1030, 1040, 1045, 1050

- Cr-MO: SCM430, SCM415, SCM435, SCM440

- Ni-Cr-MO: SNCM415, 4140, 4130, 4340

- Aluminum Series: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

- Brass Series: CDA3600, CCDA3604, 544, 932

Surface Treatment Options #

We recognize the importance of refinement, appearance, and protection against wear and corrosion. Our surface treatment solutions enhance the aesthetics, durability, and functionality of every component.

- Sandblasting

- Paint

- Anodizing

- Powder Coating

- Electroless Nickel

- Galvanizing

- Passivation

- Chromate

Additional Manufacturing Capabilities #

Our expertise covers a wide range of manufacturing processes, ensuring a one-stop solution for your component needs:

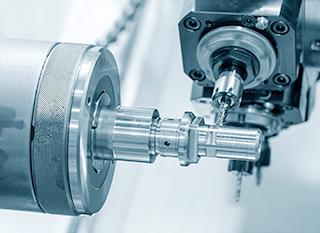

DMS CNC Turning Service

DMS CNC Turning Service

DMS CNC Milling Service

DMS CNC Milling Service

DMS Aluminum Extrusion Service

DMS Aluminum Extrusion Service

DMS Metal Pipe & Sheet Metal Bending Service

DMS Metal Pipe & Sheet Metal Bending Service

DMS Metal Welding Service

DMS Metal Welding Service

DMS Metal Forging Service

DMS Metal Forging Service

DMS Aluminum Die Casting Service

DMS Aluminum Die Casting Service

DMS Plastic Injection Molding Service

DMS Plastic Injection Molding Service

DMS OEM Manufacturing Service

DMS OEM Manufacturing Service

Streamlined Sourcing in Three Steps #

- Get a Quote: Submit your manufacturing drawing and order details. Receive a quote within 48 hours.

- Quality Control: We select the right manufacturer, oversee production, and manage quality control.

- Receive Components: Your quality-tested components are delivered with a detailed test certificate.

Customer Experiences #

What Our Clients Say #

- Tony Fred, Senior Buyer: “We greatly appreciate the exceptional service provided, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.”

- Mich Stark, R & D Engineer: “Your outstanding service is super impressive. The work on our stainless steel bending case added value to our espresso coffee grinder. Super well done.”

- Aline Turner, SR Procurement: “Thank you for delivering our parts very fast with excellent quality. This is exactly what we expect.”

- Iris Joe, Engineering Designer: “Moving our production from China to DMS was the right decision. The marine pads look shiny with no scratches. Quality speaks for itself.”

Bringing Your Ideas to Life #

We are dedicated to transforming your concepts into reality, providing not just parts, but complete solutions for your manufacturing needs.