Advancing Metal Joining: Expertise in Welding Services #

Metal welding is a cornerstone of modern manufacturing, enabling the precise and durable joining of metal components. At DMS, we offer a broad range of welding services, leveraging advanced techniques and a skilled team to meet the unique requirements of each project.

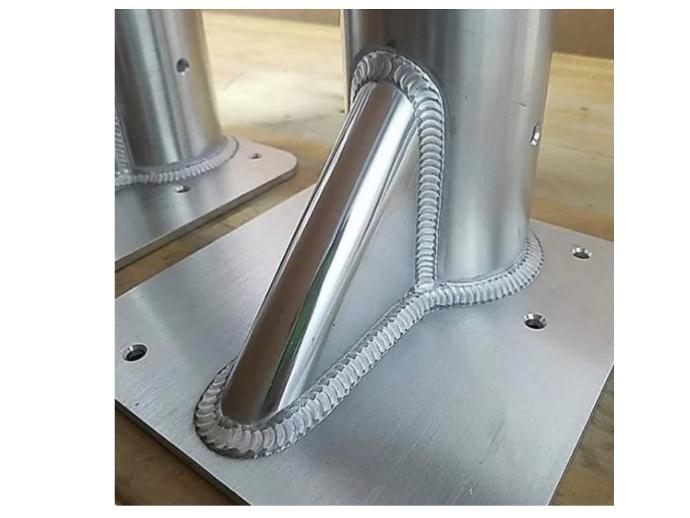

Welding Techniques and Capabilities #

Our expertise covers multiple welding processes, each suited to different applications and materials:

- Arc Welding: A versatile method for joining metals using an electric arc.

- MIG Welding (Metal Inert Gas): Ideal for efficient, high-strength welds, especially in production environments.

- TIG Welding (Tungsten Inert Gas): Delivers precise, clean welds, making it suitable for delicate materials and intricate designs.

- Spot Welding: Utilizes digital controls for consistent, reliable joints, particularly in sheet metal work.

- Laser Welding: A modern, low-temperature solution that minimizes heat input, preserving material properties and achieving fine, high-quality welds.

Our Approach: Value, Quality, and Customization #

We are committed to delivering maximum value through:

- Competitive and reasonable pricing

- Customization based on customer preferences

- Uncompromising quality standards

- On-time delivery, including express and rush order options

Typical lead times include:

- Quotation within 24 hours

- Production in 35 days

- Express service in 72 hours

- Rush order delivery in 25 days

Materials We Weld #

Our welding services accommodate a wide variety of metals, including:

- Aluminum (45%)

- Stainless Steel (15%)

- Steel (20%)

- Others (20%)

Available Material Grades #

- Stainless Steel Series: 300 Series (SUS303, SUS304, SUS304L, SUS316, SUS316L, SUS317, SUS317L), 400 Series (SUS420J2, SUS430, SUS434, SUS442)

- Steel Series: Carbon steel (12L14, 12L15, 1018, 1117, 1141, S1020, 1030, 1040, 1045, 1050), Cr-MO (SCM430, SCM415, SCM435, SCM440), Ni-Cr-MO (SNCM415, 4140, 4130, 4340)

- Aluminum Series: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

- Brass Series: CDA3600, CCDA3604, 544, 932

- Titanium Series: Grade 1 to Grade 28

- Magnesium Series: AMS 4375 - AZ31B-O Sheet/Plate, AMS 4376 - AZ31B-H26 Plate, AMS 4377 - AZ31B-H24 Sheet/Plate, AMS 4382 - AZ31B-O Plate

Welding Equipment and Capacity #

- 9 MIG welding stations

- 3 TIG welding stations

- 4 spot welding stations with digital controls

The Welding Process: An Overview #

Welding joins metal components by melting and fusing them together, often with the addition of a filler material. As the metal cools, it solidifies, forming a strong bond. The process requires skilled operators and appropriate equipment to ensure optimal results. While each technique—MIG, TIG, spot, or laser—has its nuances, all rely on the principles of heat, fusion, and solidification.

Surface Treatment for Enhanced Performance #

Beyond welding, we offer a range of surface treatments to improve the appearance, durability, and corrosion resistance of your components:

- Sandblasting

- Paint

- Anodizing

- Powder coating

- Electroless nickel

- Galvanizing

- Passivation

- Chromate

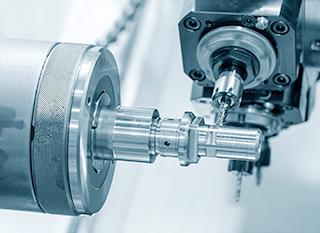

Integrated Manufacturing Services #

Our capabilities extend beyond welding, providing a seamless experience from design to finished product. Additional services include:

- CNC Turning

- CNC Milling

- Aluminum Extrusion

- Metal Pipe & Sheet Metal Bending

- Metal Forging

- Aluminum Die Casting

- Plastic Injection Molding

- OEM Manufacturer Service

Our Process: From Quote to Delivery #

- Get a Quote: Submit your manufacturing drawings and order specifications. Receive a quote within 48 hours.

- Quality Control: We select the right manufacturer, oversee production, and ensure rigorous quality control.

- Receive Components: Your quality-tested components are delivered with a detailed test certificate.

Customer Feedback #

Our clients value our commitment to quality, speed, and service. Here are a few words from those who have partnered with us:

- “Exceptional service and great-looking CNC parts have contributed to our research success.”

- “Outstanding service and excellent quality on our stainless steel bending case.”

- “Fast delivery and excellent quality—exactly what we expect.”

- “Moving production to DMS was the right decision; quality speaks for itself.”

For more information or to discuss your project requirements, contact us.